Co-op at Cuberg: Lithium Battery Thermal Study

As part of Northeastern’s Co-op program, I worked at Cuberg for 9 months from July 2020 -March of 2021. At Cuberg I worked in their R&D department, supporting the development of the next generation of lithium metal batteries. I worked on the thermal analysis of the pouch cells to help inform electrolyte formulation and the design for the battery management system.

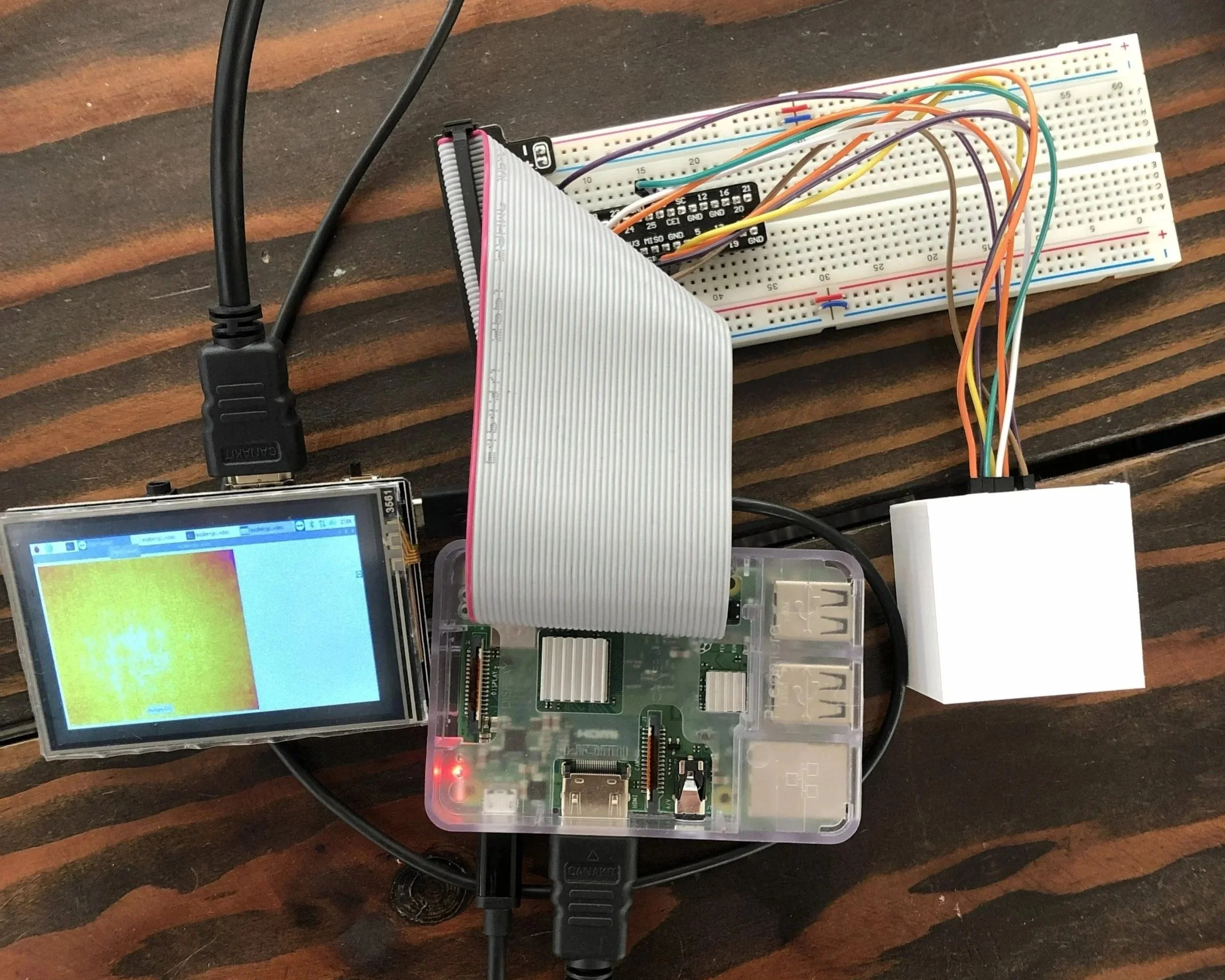

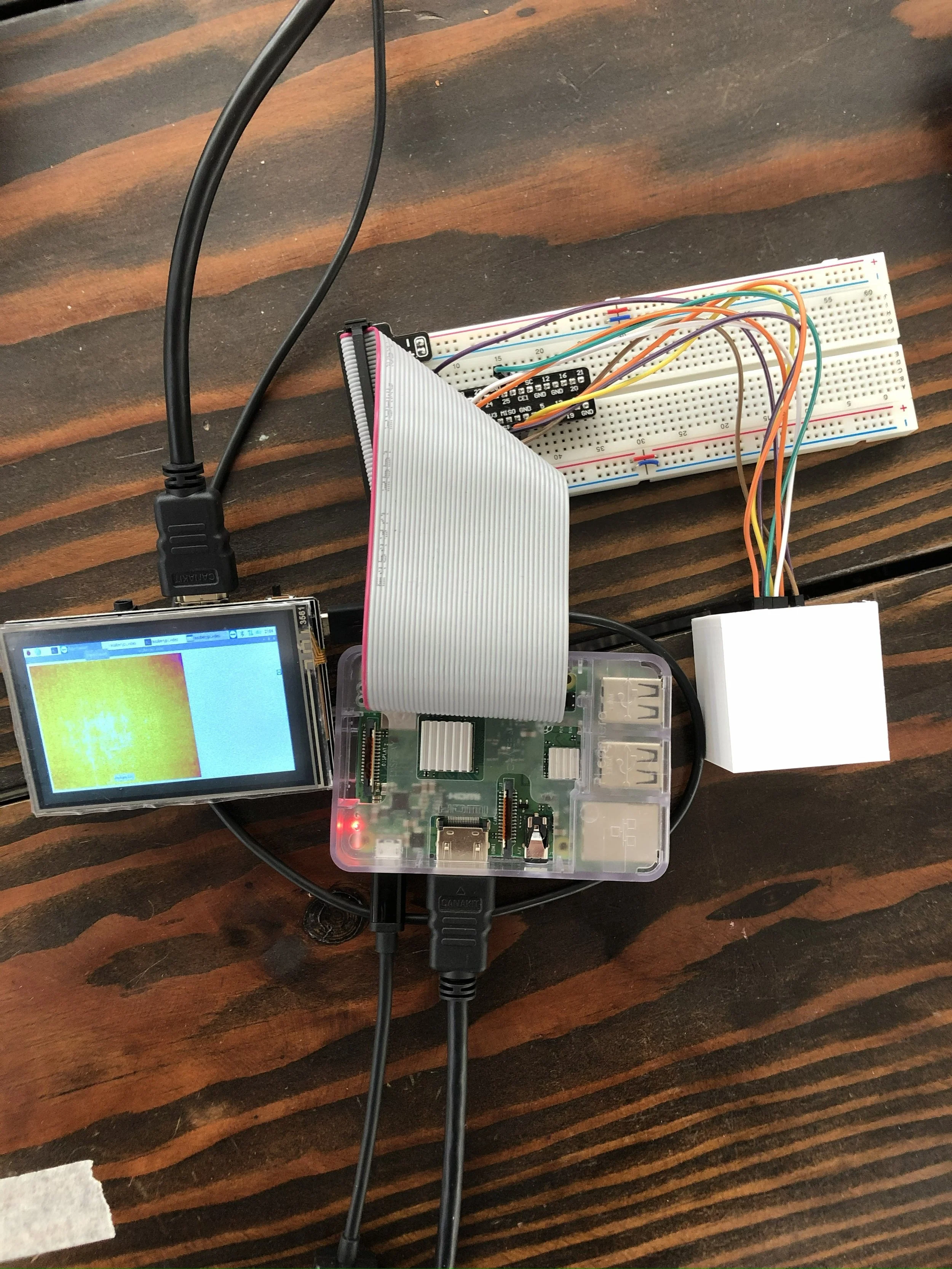

I wote a python script to control an open source Flir Lepton camera connected to a raspberry pie to record the battery pouch cells.

An IR video I recorded of pouch cell intentionally over charged to to explosion (explodes around the 22 second mark).

Objective 1 - Safety Testing

Record how the battery cells change temperature leading up to a failure (explosion). Failure was achieved by heating, puncturing, shorting, or over charging the battery cell.

Objective 2 - Cell cycling performance

Record thermal changes in battery pouch cells while charging/discharging to determine battery defects.

Challenges

Limited budget prohibited any “plug and play” thermal imaging solutions.

Complicated integration of open source hardware and software components combined with no prior experience with raspberry pie, limited internal resources and tight deadlines.

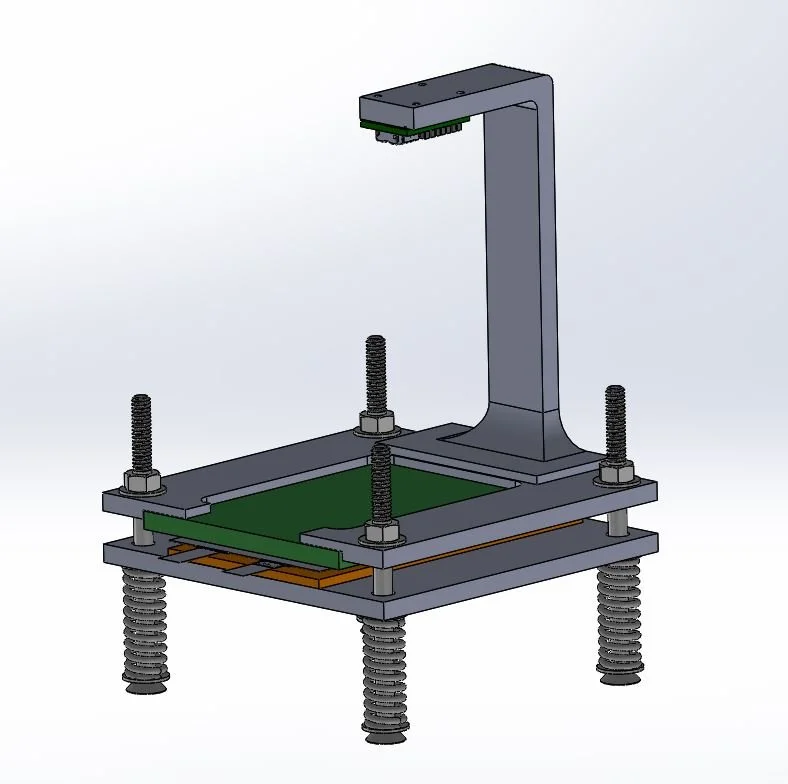

Battery cells are fixtured with steel plates at a specific pressure to prevent dendrite formation - steel is opaque in the IR specturm.

Key Outcomes

Successfully integrated my python script with the raspberry pie, and Flir Lepton IR camera.

Successfully built a fixture by incorporating an IR transparent window into the fixture made from ZnS material.

Incorporated a LCD screen and Bluetooth data transmitter so test setup could be used wirelessly in a glovebox.

Recorded and presented insightful data on locations where hotspots form on the battery cell.

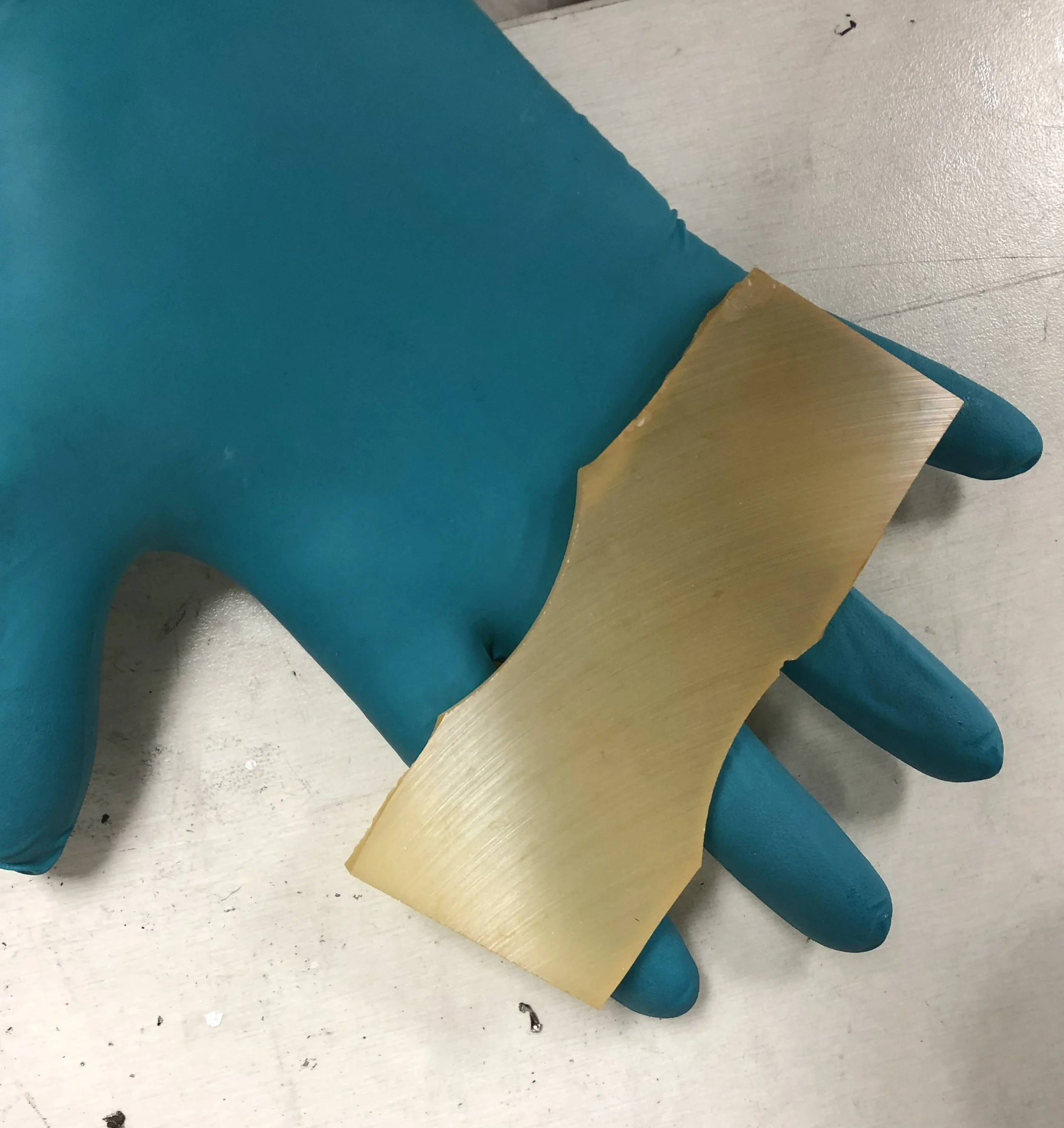

Zinc Sulfide (ZnS) material sample that was machined for IR window.

The battery cell pictured above was clamped down to a specific pressure to mitigate dendrite formation. Because of this, a custom fixture incorporating a ZnS material was used to view the thermal changes of the battery while cycling.

Pictured above is one setup used to record the thermal imaging of the battery cells.

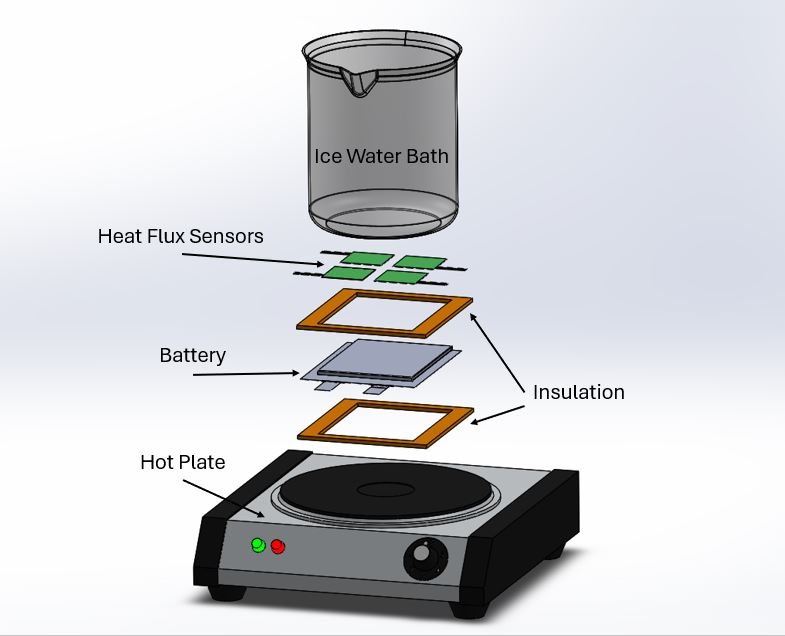

Coefficient of Thermal Conductivity Experiment

Objective

Determine coefficient of thermal conductivity through the thickness of the pouch cell.

Challenges

No theoretical conduction coefficients existed for the proprietary materials used in the cell stack.

No method was known to our team on how to experimentally determine the conduction coefficient through experimentation.

Key Outcomes

I came up with a way to experimentally determine the coefficient of friction using a known hot and cold temperature source.

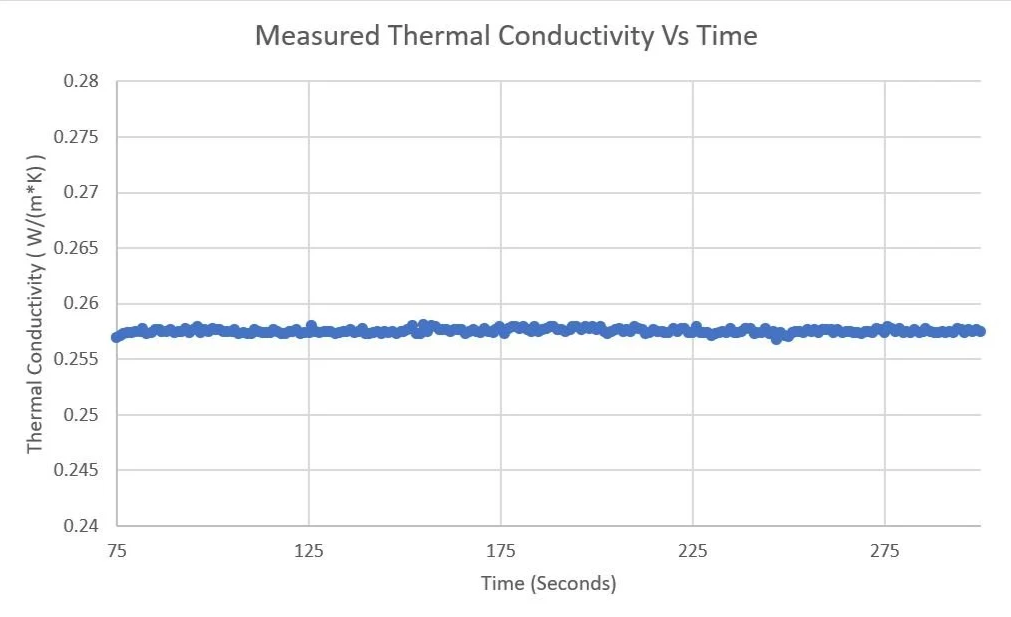

Designed experiment and successfully determined the k value with high accuracy using K = Q*t/(Th-Tc) .

The thermal coefficient of conductivity was measured to be 0.257 ± 0.004 W/(m·K)