Datacolor - Mechanical Engineer (Jul 2022 - Sep 2024)

Datacolor designs and manufactures high-precision optical measurement devices that quantify color based on reflected or transmitted light spectra.

I was a key member of a small engineering team and played a critical role in the development and production release of multiple new products including:

Spectro P Series

Spectro 55

Checkr Video

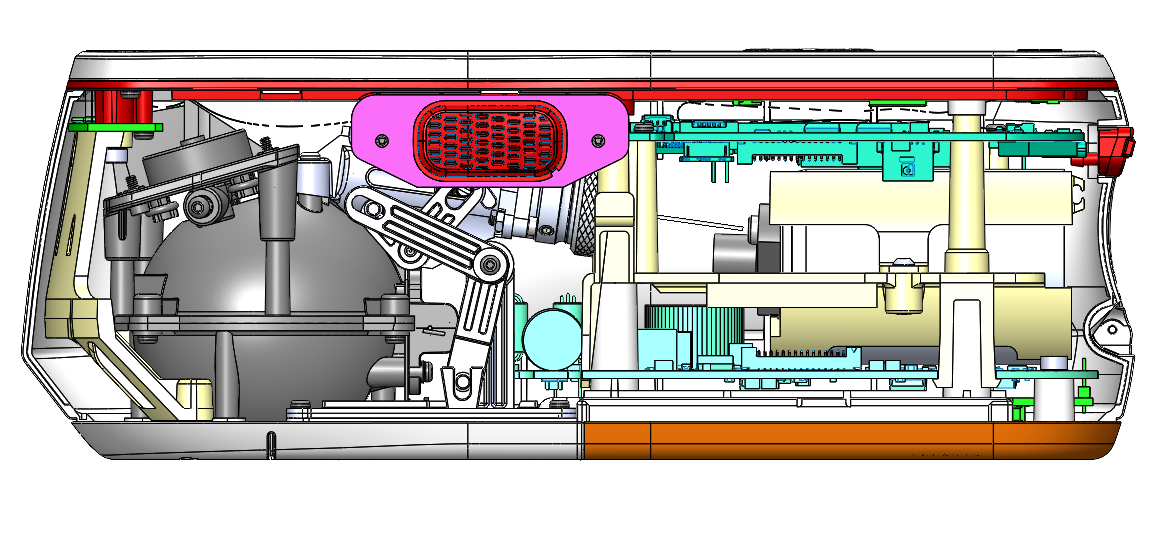

Spectro P Series

Datacolor’s new portable handheld spectrophotometer - optical color measuring device.

Objective

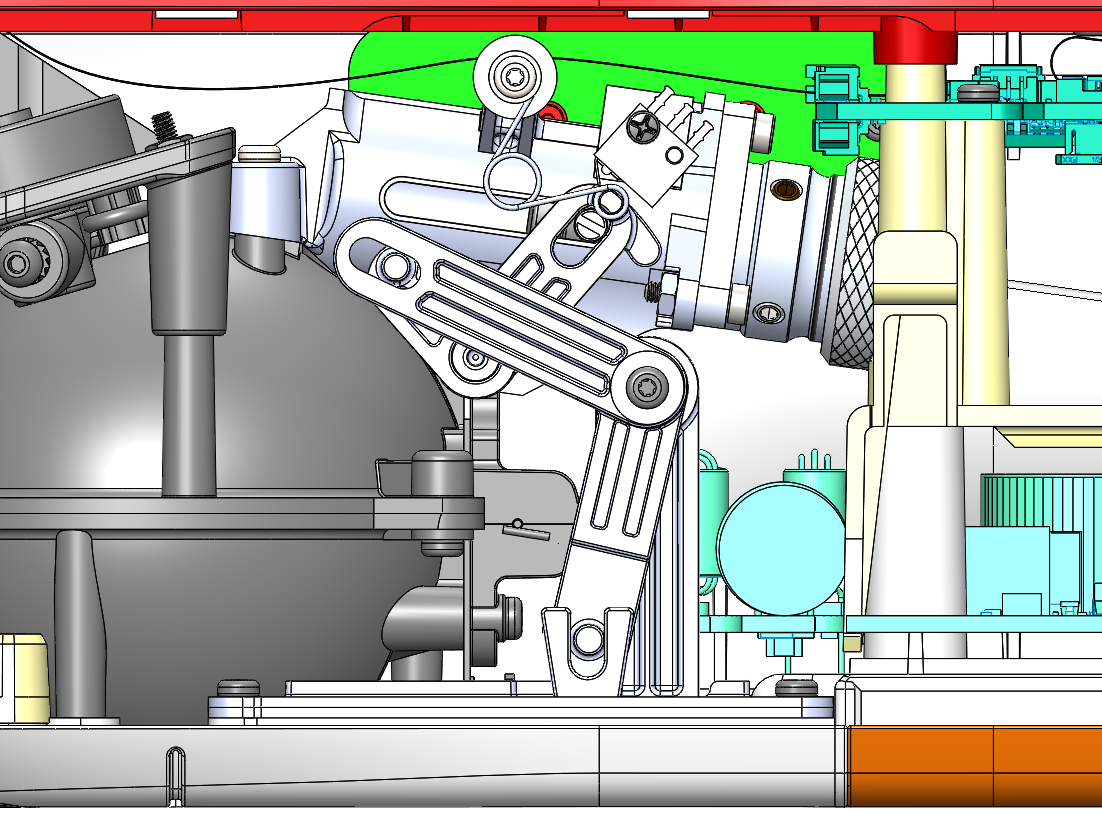

Create a mechanical linkage to toggle a zoom lens while holding extremely tight tolerances for lens x,y,z position and angle.

Challenges

Linkage mechanism was confined to a very small footprint and pivot points and travel distances were highly constrained.

Linkage mechanism needed to be actuated with a finger tip amount of force, but also apply enough force to reliably hold lens in place.

Pictured above is a close up of the zoom tube and linkage mechanism I designed for the product.

Key Outcomes

Designed a custom torsion spring to apply the exact amount of force needed to retain the zoom lens in the correct position

Used FEA, Solidworks motion analysis, Free-body diagrams, and testing to determine the correct pivot positions and arm lengths to build the linkage mechanism that met all requirements.

Created life cycle test fixture to verify linkage assembly actuation to hundreds of thousands of actuations.

Spectro 55

New benchtop spectrophotometer

Objective

Design a new spectrophotometer with a smaller footprint and is less expensive than the older Spectro 200 model.

Design sheet metal housing to be easier to service - less screws, electronics ports on lower sheet metal portion.

New Spectro 55

Old Spectro 200

Challenges

Solidworks models for the old Spectro 200 model were not stable.

Designing sheet metal enclosure to require only two fasteners.

Key Outcomes

Successfully built and verified the 3D printed prototype on the first attempt and met the tight product release deadline.

Built robust parametric Soldiworks models using best practices.

Learned Keyshot to develop renderings of product.

New Spectro 55

Old Spectro 200

Spyder Checkr Video

Handheld color chart

Objective

Work with outside industrial designer and oversee mechanical elements of design including:

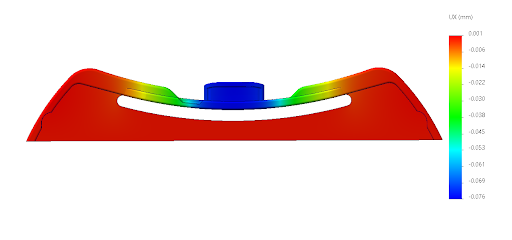

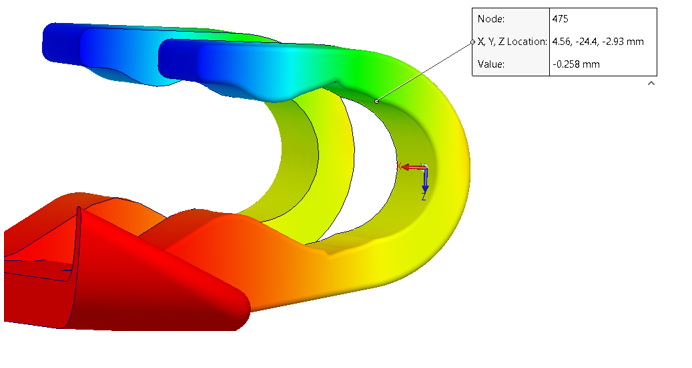

Detent mechanism utilizing bumps on a spine interfacing with indentations on hooks.

Push latch mechanism.

Challenges

Aesthetic changes affected the mechanical elements of the design:

Push latch mechanism required too much force.

Detent mechanism was too weak.

Key Outcomes

Used Solidworks FEA and experimentation to determine root causes for mechanical failures.

Successfully designed new push latch and detent mechanisms to meet requirements.